The company applied for the cooperation project from 2014 to 15 years, and in March 2016, it formally entered into cooperation with zhangjiagang hengye special resin co., ltd. and invested in infrastructure. Zhangjiagang hengye special resin co., LTD. Is a sino-foreign joint venture established by Shanghai chemical industrial park guomao chemical co., LTD and the UK AYA chemical co., LTD. The company registered capital of 25 million usd, the main development direction is chemical new material and fine chemical products development and production and management. The company was registered in March 2007, with a production capacity of 50,000 tons of epoxy resin in May 2007, and a 10,000-ton liquid epoxy resin project in September 2008 was completed and put into production.

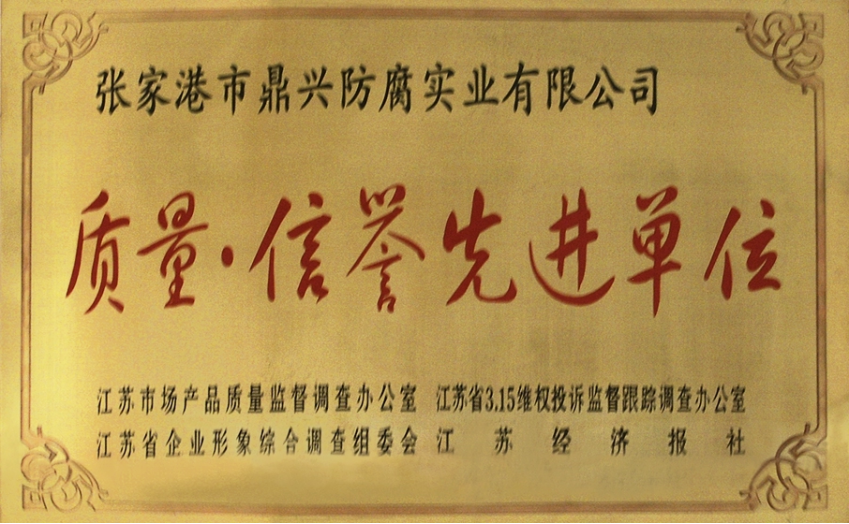

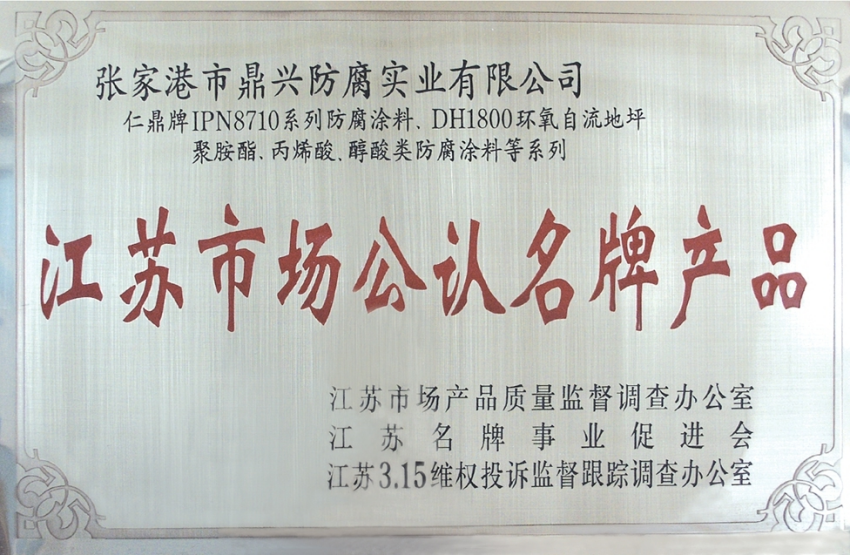

MORE>Zhangjiagang dingxing anticorrosion industrial co., LTD was founded in 1990, which is the production of "rending" brand (registered trademark) series coatings Companies.Located on the south bank of the Yangtze river, zhangjiagang industrial park, zhangjiagang city, which is beautiful and economically developed.East by Shanghai, south to su xichang, north to nantong, convenient transportation.Is the domestic production of anti-corrosion paint variety of the factory.

MORE>Zhangjiagang dingxing anticorrosion industrial co., LTD was founded in 1990, which is the production of "rending" brand (registered trademark) series coatings Companies.Located on the south bank of the Yangtze river, zhangjiagang industrial park, zhangjiagang city, which is beautiful and economically developed.East by Shanghai, south to su xichang, north to nantong, convenient transportation.Is the domestic production of anti-corrosion paint variety of the factory.

MORE>